Industrial IoT Spending Skyrockets As Manufacturing Sector Braces for Change

According to a recent report from IoT Analytics, global spending on industrial internet-of-things platforms is expected to increase at a compound annual growth rate of 40 percent over the next few years, from $1.67 billion in 2018 to $12.44 billion in 2024. “Autonomous IoT platforms,” says Choice IOT’s CEO Darren Sadana, “are beginning to replace the large software-driven manufacturing execution systems currently in place in the manufacturing sector.” Sadana, whose company specializes in wireless connectivity for IoT solution providers, adds, “One thing that’s crucial at this point is for both manufacturers and platform developers to make sure they’re building the infrastructure they’ll need to support these new capabilities.”

The changes now taking place in manufacturing are often referred to as Industry 4.0, or the fourth industrial revolution. The first three industrial revolutions, Sadana notes, were precipitated by the transition from:

- Handwork to machinery (late 18th century),

- Electrification and standardization (late 19th-early 20th century),

- Computerization (beginning c. 1950).

Among the basic technologies of Industry 4.0 are artificial intelligence, additive manufacturing (also known as 3D printing), and blockchain, which provides verifiable control of the manufacturing supply network.

While Industry 4.0 is often discussed as though it were already firmly in place and delivering trackable benefits, the reality, Sadana notes, is that the revolution is just now getting underway. Many U.S. manufacturing plants are more than 20 years old, and fewer than 14 percent of the machines on shop floors are able to transmit and receive real-time data. These older machines are not only not equipped to operate in an Industry 4.0 environment, they are also prone to breakdowns, which account for up to $50 billion per year in lost manufacturing time.

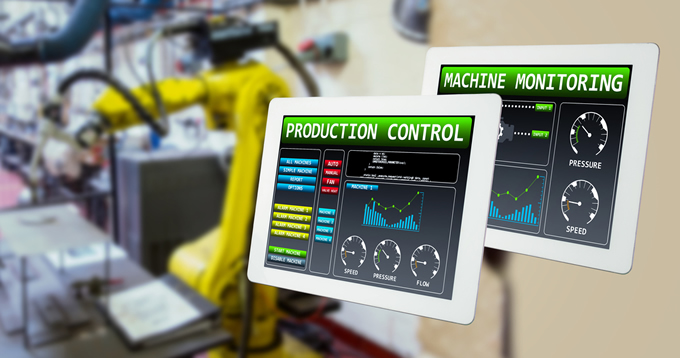

The bulk of manufacturers considering the use of industrial IoT are thus currently in assessment mode: increasing their ability to understand, monitor, and predict the processes they already have in place. In addition to systems and equipment, manufacturers are reviewing their overall management and personnel structures to ensure that the necessary training, understanding of roles, motivation, and feedback—including the management of an emerging ecosystem of industrial service providers—will be in place to make sure that Industry 4.0 takes off as planned.

They are also paying close attention to digital infrastructure. “All the components of Industry 4.0,” says Sadana, “from fundamental technologies like AI and blockchain to multiple interlocking solutions platforms, rely on constant access to each other and to the cloud, which in turn requires constant, dependable 24/7/365 wireless connectivity. In planning and managing their businesses, manufacturers should be aware that it is possible to obtain accurate, current information—including pricing and contract requirements—about this essential commodity.”

As Published in manufacturingtomorrow.com : Article Link